InSTREAM Project Characterizes and Models Turbulence from Tank Test to Tidal Channel

The recently completed InSTREAM project assessed fundamental differences in turbulent flow measured in the field, generated in a tank and simulated in a numerical model

To mitigate the risk and uncertainty associated with turbulent flows in tidal channels, developers often use tank experiments and numerical simulations to assess the power and loading performance of a turbine. However, it remains unclear if these controlled flows can be accurately scaled up to represent the natural turbulence present in tidal channels.

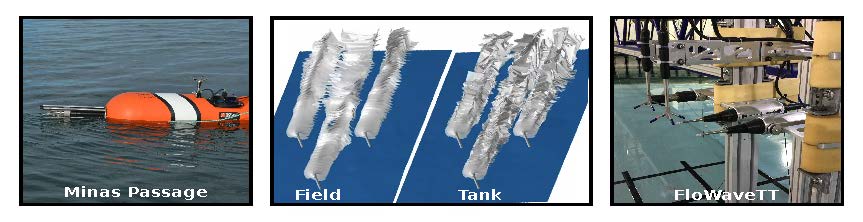

The InSTREAM project compared numerical simulations (centre) that represented measured turbulent flow regimes in the field (left) and in the laboratory (right).

PROJECT DESCRIPTION

The difficulty in translating between model, tank and field environments motivated the In-Situ Turbulence Replication, Evaluation And Measurement (InSTREAM) project. The three-year project was conducted by a research consortium comprising six commercial and academic entities in the UK and Canada. The project was given the prestigious EUREKA designation, and was co-funded by the Offshore Energy Research Association and InnovateUK. More information can be found on the Eureka project page

OBJECTIVES

The main goal of the InSTREAM project was to determine the appropriate scaling between the turbulent flow conditions in a tank and in a tidal channel, so that numerical simulations of such

flows can be used to estimate uncertainties on turbine performance. The project included the development of a sensor system that combined acoustic (Doppler), and non-acoustic (electro-magnetic and shear probe) technology to create a system that could be used in both laboratory and field applications. The system was successfully deployed at the FloWaveTT Energy Research Facility and in the Minas Passage, Bay of Fundy. Numerical simulations – representing the measured tank and field conditions – were then performed.

KEY OUTCOMES

As expected, the InSTREAM project found significant differences between the turbulence characteristics in the tank and in the field. The 3D eddies observed in the field were, in relative terms, about three times larger than those generated in the tank, resulting in considerable differences in power and fatigue loading. A scaling method has been developed to allow direct comparison and translation between the two flow regimes. This scaling greatly increases the usefulness of tank testing and numerical modeling, and can be reproduced for other test tanks. It also allows site-specific field measurements to be translated to tank experiments, enabling numerical models (validated by tank experiments) to be used for reliable and realistic estimation of turbine and array performance.