Replacing Clear Heat-Shrink Tubing on SMC cables

Each SMC cable that protrudes from the nose cone of a VMP, MicroRider, or MicroSquid is encased in 2 pieces of clear heat-shrink tubing. The clear tubing insulates the exposed metal of both the SMC cable shaft and the nut from the inner wall of the probe holder. Damaged tubing must be replaced so that the probe does not make electrical contact with the probe holder.

NOTE: If your SMC cables have moisture damage, replacing the heat-shrink tubing is NOT a sufficient repair. The entire SMC cable must be replaced.

To replace the heat-shrink tubing:

1) Remove the old tubing using a pair of wire cutters to snip the length of the old tubing. Alternatively the old tubing can be easily pulled off the cable by reheating the tubing. Note that there is tubing on both the nut of the SMC cable and the shaft of the SMC cable. Both pieces must be removed. You should now have a clean, exposed SMC cable and nut. Do not remove the identification label from your SMC cable.

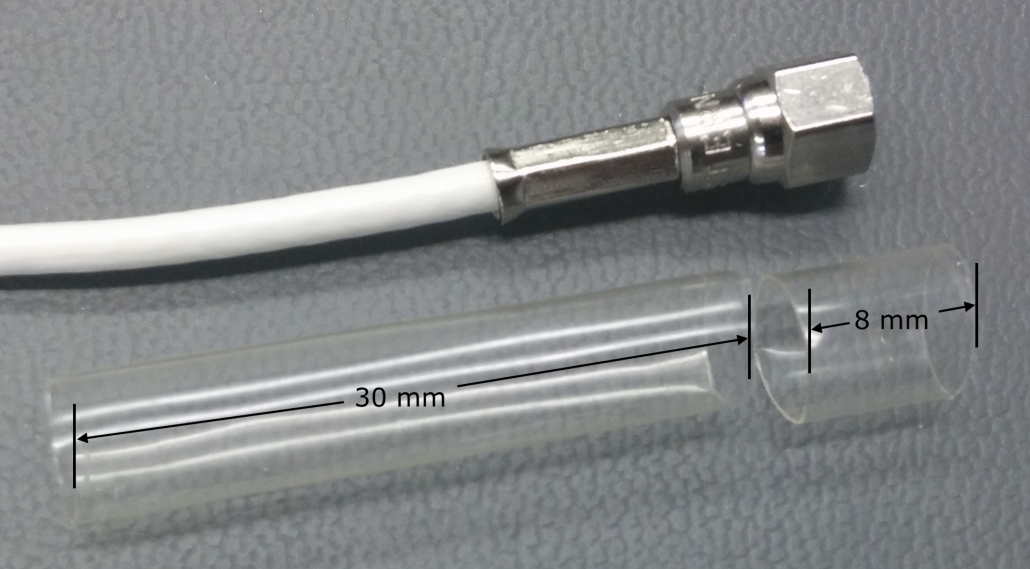

2) Cut two pieces of new clear heat-shrink tubing to length: one piece covers the nut on the end of the SMC cable, 8 mm, and one piece covers the metal shaft, 30 mm.

SMC cable after the old tubing as been removed, and two pieces of replacement tubing that have been cut to length. Note that this cable has no identification label. Do not remove the identification label from your SMC cable.

3) Place the tubing over the shaft, 7 mm behind the threaded face of the SMC nut. The tubing should protrude slightly past the end of the metal shaft so that when the tubing shrinks it will cling to the top of the shaft.

The heat shrink tubing covering the shaft of the SMC cable before heat has been applied. The heat shrink is positioned 7 mm behind the front of the nut.

4) Heat the tubing on the shaft, rotating the cable gently to ensure that all sides of the shaft are heated evenly . Do not overheat the tubing. Apply only enough heat to shrink the tubing until it touches the cable. Excessive heating will damage the tubing. The nut must be left to spin freely after the tubing has been applied.

5) Place the tubing over the nut . The tubing should protrude 1 mm past the threaded end of the nut. This will leave enough heat-shrink tubing to cup the base of the nut when heated.

6) Heat the tubing on the nut, rotating gently to ensure all sides of the nut are heated evenly. Do not overheat the tubing. The tubing will shrink and tighten around the nut. Ensure that the nut is able to rotate freely.

The SMC cable with one piece of heat-shrink tubing on the nut and one piece of tubing on the shaft. The nut can still rotate freely.