Technical Training Events

We are pleased to offer the turbulence community both in-person and online technical instrument training events. These sessions cover instrument handling, maintenance, best practices for operations, and data processing. Rockland is committed to hosting events in a multi-institutional format, allowing participants to benefit from a collective pool of expertise and experience.

Note that Rockland is planning to hold future group technical instrument training events in between April and May of a given year, focusing on the main categories of microstructure instruments (profilers and OMG systems). These events will be open to both in-person and online participation, subject to sufficient registered participants. Please visit our events page to see all currently scheduled Rockland Technical Training events or reach out to us to be notified about future training opportunities at Rockland support.

If you require immediate assistance or customized training arrangements, please contact us directly at Rockland support.

Typical Instrument Training Sessions

Ocean Turbulence Measurement Probes and Sensors

• Identify the components of a shear probe and explain the underlying theory of operation

• Describe the shear probe calibration technique

• Identify the components of an FP07 thermistor

• Compare the sensor limitation of the shear probes and thermistor

• Describe the SBE7 Micro Conductivity sensor

Introduction to the Rockland Microstructure Measurement System

• Locate and identify sensors, probes, and axes of orientation

• Install and remove probes

• Correctly disassemble and assemble the microstructure measurement instrument

• Differentiate between a piston seal and a face seal

• Locate and identify the circuit boards and understand their functions

• Describe the flow of information and analog signal processing that occurs in a Rockland microstructure measurement instrument

• Confirm proper orientation of the shear probes

Instrument Software

- Become familiar with the Rockland Data Logger (RDL) Data Acquisition System

- Understand Rockland data format, setup files and configuration settings

- Establish instrument communication

- Become familiar with our Zissou Essentials instrument data review software

Pre Deployment Checks

• Perform a bench test with test probes; process and interpret the data

• Identify every sealing surface on the instrument and confirm its integrity

Instrument Maintenance

• Disassemble the instrument into its components

• Determine if an O-ring needs to be replaced

• Recognize corrosion and moisture damage

• Perform recommended post-cruise and annual maintenance

• Reassemble the instrument and all of its components

Data Processing Tools

- Introduction to Data Processing Tools

- Perform in situ calibrations of temperature probes

- Review how to integrate platform data during instrument data post-processing

Technical Training Events

Rockland strives to engage with the broader turbulence community by hosting regular workshop events, which in addition to covering some of our technical training material, allow us to expand on a variety of turbulence data-processing topics and provide exposure to other sampling techniques. In the past Rockland has hosted regular Ocean Microstructure Glider (OMG) workshops fostering collaboration with the ocean glider and AUV community. Other focused workshops are possible covering different observing platforms as well as focusing on current research topics. Workshop events are a great way to become familiar with our instruments and foster collaboration in the turbulence community. Please follow our events page and Social Media channels to learn of future events and offerings.

Rockland Hosts OMG Ocean Microstructure Glider Workshop in Gothenburg, Sweden

We’re excited to announce that Rockland Scientific is planning to hold an Ocean Microstructure Glider (OMG) Workshop in the Spring of 2025, in collaboration with the Voice of the Ocean Foundation (VOTO) in Gothenburg, Sweden! 🇸🇪 📅 When: May 5-9, 2025 📍 Where: Gothenburg, Sweden This workshop brings together ocean scientists, glider users, and marine […]

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

0

0

Nicole Dovak

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Nicole Dovak2025-02-21 16:10:182025-04-07 00:16:04Rockland Hosts OMG Ocean Microstructure Glider Workshop in Gothenburg, Sweden

https://rocklandscientific.com/wp-content/uploads/2019/03/Capture.png

276

261

caorda

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

caorda2019-03-06 16:05:162019-03-07 15:45:23Ocean Microstructure Glider Workshop, OMG 2019, Victoria BC, June 10 – 14, 2019

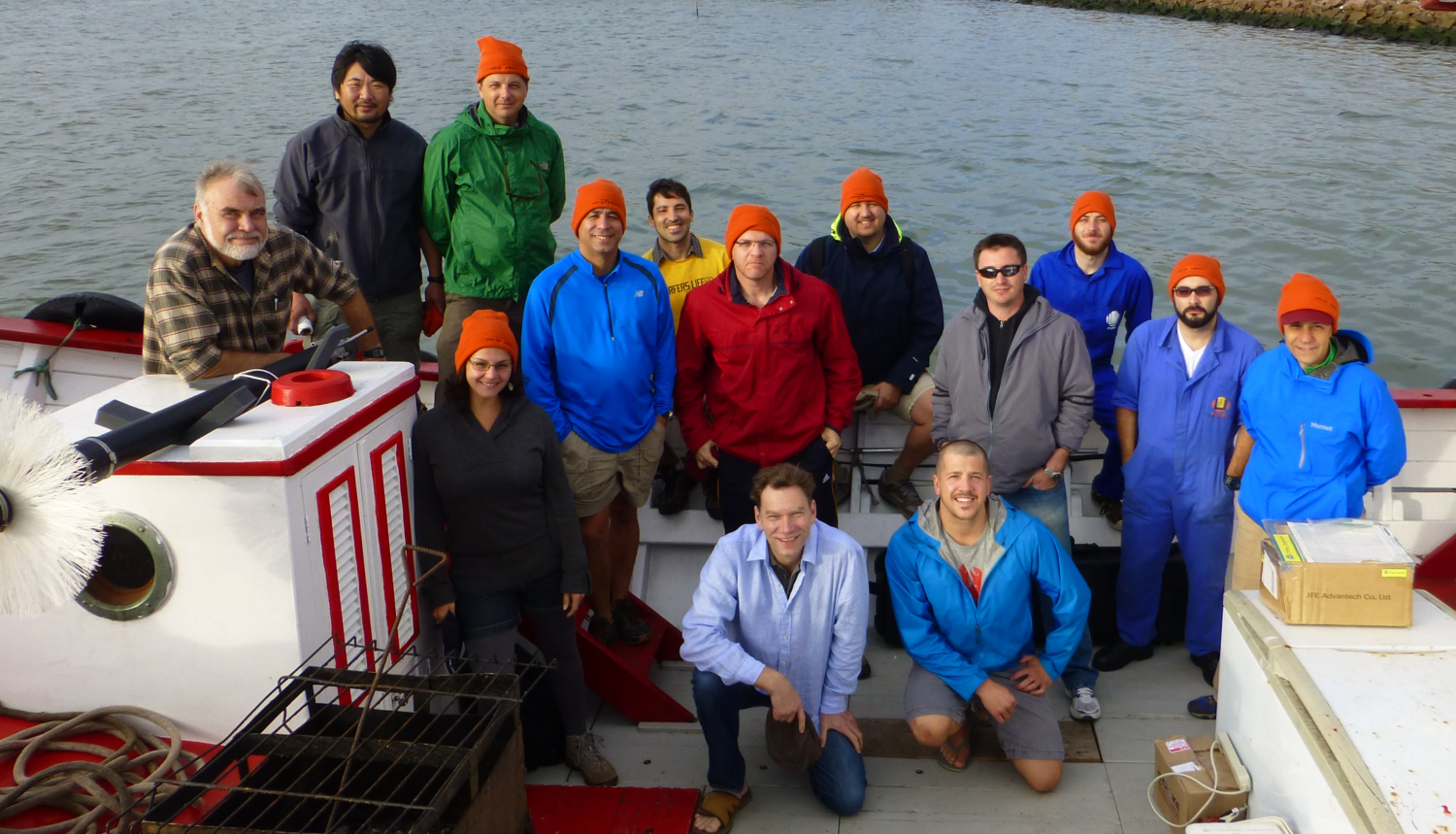

Ocean Turbulence Workshop in South Africa Lead by Rockland Microstructure Specialists

“UKZN’s Department of Civil Engineering held the first ever workshop on Ocean Turbulence in South Africa. The workshop was facilitated by Derek Stretch, Professor for Environmental Fluid Mechanics, with funding provided through an Office of Naval Research (ONR) global grant. Turbulence at microstructure scales (a centimetre or less) is an important mechanism for mixing in the […]

https://rocklandscientific.com/wp-content/uploads/2019/01/DSCF5933-1.jpg

3456

4608

caorda

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

caorda2019-01-22 09:01:482019-01-22 15:18:21Ocean Turbulence Workshop in South Africa Lead by Rockland Microstructure Specialists

Ocean Microstructure Glider Workshop, OMG 2018, Bermuda, May 28 – June 1, 2018

OMG 2018 is a specialized training program for Rockland turbulence measurement systems that are integrated with ocean gliders. OMG 2018 will be hosted by the Mid-Atlantic Glider Initiative & Collaboration (MAGIC) at the Bermuda Institute of Ocean Sciences. Training will be optimized for both scientists and technicians and facilitated by instrument specialists from Rockland Scientific. […]

https://rocklandscientific.com/wp-content/uploads/2018/07/DSCF6956.jpg

3456

4608

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2018-02-08 12:03:322018-08-02 15:52:37Ocean Microstructure Glider Workshop, OMG 2018, Bermuda, May 28 – June 1, 2018

Ocean Turbulence Workshop : 22 – 26 January 2018

With support from the ONR-Global program, the Environmental Fluid Mechanics Lab at UKZN, in collaboration with Rockland Scientific, is organizing a training workshop on Ocean Turbulence in January 2018. Rockland’s Dr Rolf Leuck, a leading international expert on the measurement of ocean microstructure, will lead the workshop. The course deals with both theoretical and practical […]

https://rocklandscientific.com/wp-content/uploads/2017/11/RSI-logo-vert.jpg

800

800

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2018-01-11 10:58:282018-08-02 15:42:41Ocean Turbulence Workshop : 22 – 26 January 2018

Well-Attended Inaugural China Ocean Turbulence Workshop (COTW 2017) Comes to a Close

QINGDAO, CHINA, November 3, 2017 – Rockland Scientific Inc. (Rockland), in cooperation with partners JFE Advantech (JFE) and Ocean Science & Technology Company, Inc. (OST-Qingdao), have successfully concluded the inaugural China Ocean Turbulence Workshop (COTW) in Qingdao this week. The 2017 COTW, with 45 delegates, brought together a wide range of Rockland instrument users from across […]

https://rocklandscientific.com/wp-content/uploads/2017/11/RSI-logo-vert.jpg

800

800

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2017-11-02 08:00:342020-03-31 12:05:31Well-Attended Inaugural China Ocean Turbulence Workshop (COTW 2017) Comes to a Close

The 1st Summer School of Upper Ocean Turbulence, Gdańsk 2016

The 2 week course included a 2 week intensive training period (25 July – 5 August) with lectures by a diverse set of international experts that intend to cover a broad spectrum of problems ranging from application of spectral methods in turbulence data analysis to numerical methods in turbulence research. The last week of the […]

https://rocklandscientific.com/wp-content/uploads/2017/11/RSI-logo-vert.jpg

800

800

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2017-02-07 10:26:532020-03-31 12:51:44The 1st Summer School of Upper Ocean Turbulence, Gdańsk 2016

OMG 2017: Ocean Microstructure Glider Training

Ocean Microstructure Glider training, “OMG 2017”, is a 4-day training workshop that covers all aspects of turbulence measurements using MicroRider integration with ocean glider platforms. The training workshop will cover setup, operation, maintenance, deployment and processing of turbulence data. The workshop is scheduled for April 24-27, 2017 in Victoria, B.C. Canada. Please see the OMG 2017 […]

https://rocklandscientific.com/wp-content/uploads/2017/02/OMG2017logo_large-01.jpg

363

417

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2017-02-03 12:28:462018-08-02 15:44:52OMG 2017: Ocean Microstructure Glider Training

VicTOR 2016 Success!

Thank you to everyone who attended VicTOR 2016. It was a successful week and we are happy to see so many people learning about ocean turbulence.

https://rocklandscientific.com/wp-content/uploads/2017/05/Victor_Square-300x300.jpeg

300

300

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2016-10-25 09:12:582018-08-02 15:45:30VicTOR 2016 Success!

Visitor’s Info Package for VicTOR 2016 Released

Only 2 weeks until VicTOR 2016! Please find all the information in our VicTOR 2016 Information Package.

https://rocklandscientific.com/wp-content/uploads/2017/05/Victor_Square-300x300.jpeg

300

300

Jeremy Hancyk

https://rocklandscientific.com/wp-content/uploads/2015/08/RSI-logo-horiz-300x138.png

Jeremy Hancyk2016-10-03 12:47:092018-08-02 15:46:04Visitor’s Info Package for VicTOR 2016 Released

Click here to add your own text